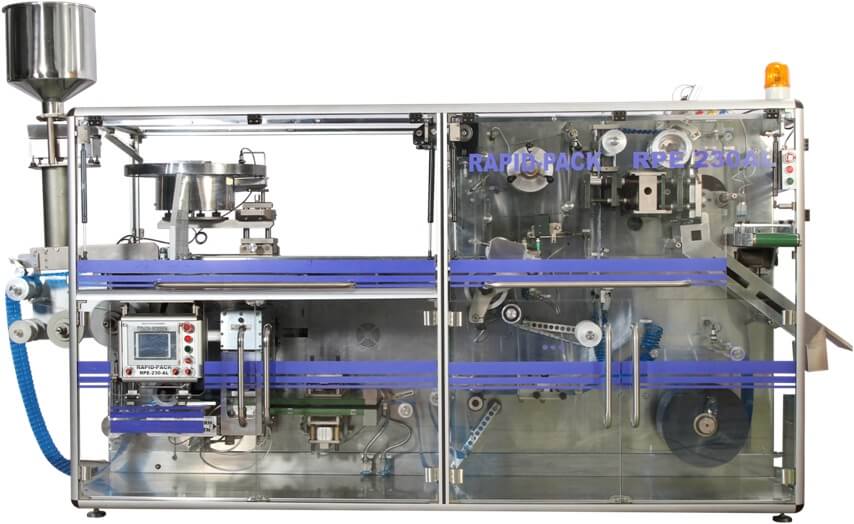

RPE 230 AL

Blister machine 230 AL is ideal for the packaging of small and medium-sized batches of solid dose products.

The modular concept of the compact blister machine allows maximum packaging flexibility.

Furthermore, the highly reliable process of the Blister machine 230 AL offers gentle product handling, easy cleaning, and fast format changeovers, as well as user-friendly operation.

All these factors contribute to the particularly high economic efficiency of the 200 AL.

Features

- Flat Forming & rotary sealing Alu Alu machine.

- The Servo motors help in intelligent control, high speed and high torque for Alu- Alu.

- Specially designed forming station for front loading and quick tool changeover.

- Guide track re-positioned to avoid accidental tablet re-entry inside the machine.

- Fully guarded, Compact design, Tool less change over.

- Specially designed quick clamping for PVC reel feed assembly & splicing device for PVC Cutting and for rejoining.

- Redesigned quick pneumatic web holding mechanism in Punch Indexing Roller

- HMI (Human Machine Interface) with touch screen relocation in a user-friendly position.

- PLC (Programmable Logic Controller

- The Compact & intelligent Power Panel

- Display of text and graphics with up to QVGA resolution

- Simple operator terminals

- Powerful Geode LX800 processor with 500 MHz clock frequency

- Equipped with 2 USB interfaces and a fast Ethernet port for exchanging data

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Technical Specification

| Max machine speed | : upto 70 cyl/min |

| Max forming area | : 200x220 mm |

| Max base foil width | : 234 mm |

| Max lidding foil width | : 230 mm |

Utilities Specification |

|

| Cooling water consumption | : 150-180 Ltr/hr |

| Air pressure consumption | : 25 CFM |

| Net weight | : 2200 Kg (Approx.) |

Machine Dimensions |

|

| Machine Length | : 3200 mm |

| Machine Width | : 1100 mm |